For all manufacturing systems where cooling water is used

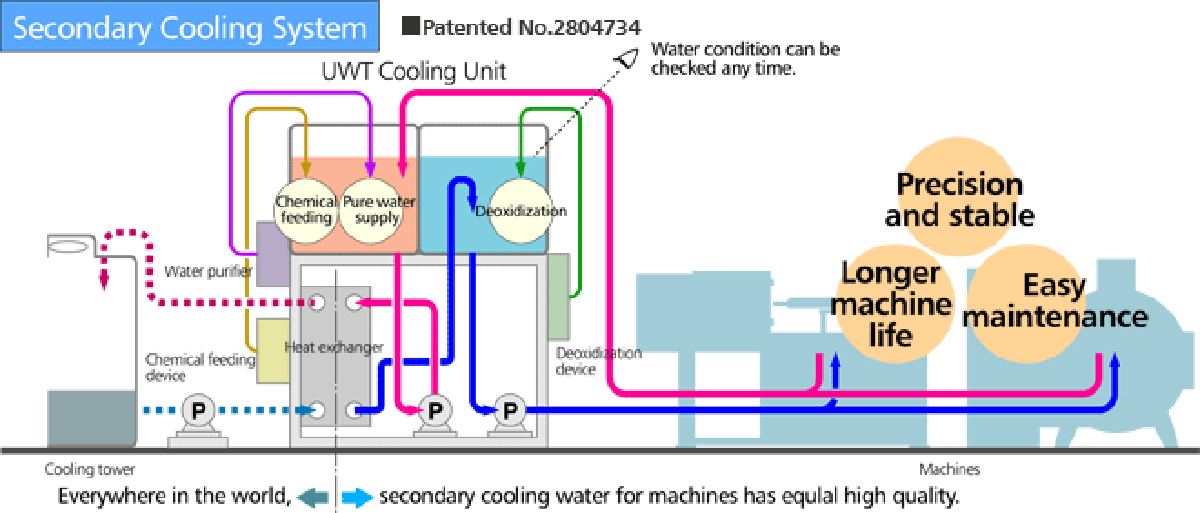

Our products make it possible to use cooling water of the equal quality everywhere in the world.

Secondary cooling systemthat leads to trouble-free cooling water,

stable manufacturing processes and energy saving.

■ Patented No.3927188

Main specifications

| Device type | Heat exchanger unit | Line to machines | Dimensions (WxLxHmm) | Tank capacity (t) | Water volume to machines (L/min) |

| UWT-250WHX | 2 lines | 2 lines | 1,100x1,600x2,434 | 1.0 | 250 (250--500) |

| UWT-300WHX | 2 lines | 2 lines | 1,650x2,200x2,434 | 1.0 | 300 (300--1,000) |

| UWT-1000WHX | 2 lines | 2 lines | 1,650x3,100x2,434 | 2.0 | 1,000 (1,000--2,000) |

| UWT-2000WHX | 2 lines | 2 lines | 1,650x3,115x2,434 | 3.0 | 2,000 (2,000--3,000) |

● Abalable for the special design.

Secondary cooling system enables complete controls on cooling water

Exquisite cooling system employed in power plants.

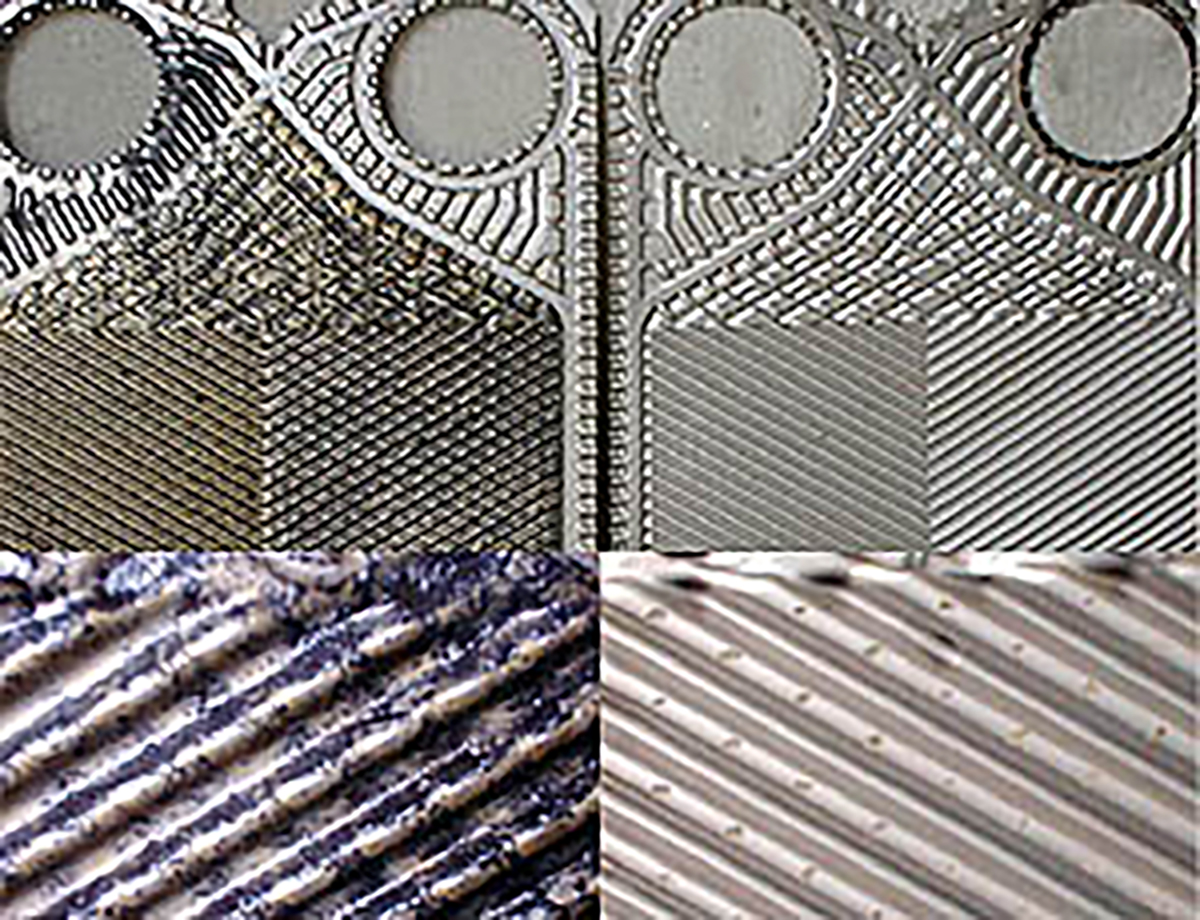

Rust in pipes of a oil-cooler, thick scale piled up in a joint and a PVC pipe (Cross-sectional area decreased 84%).

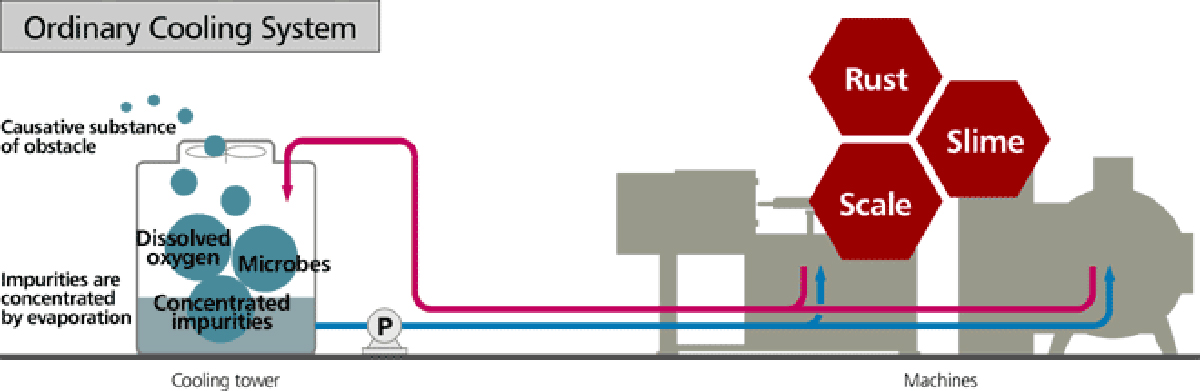

Contaminated cooling tower water causes corrosion and scaling,

which reduce cooling efficiency of molds or molding machine resulting low productivity and precision.

Controlled cooling water prevents corrosion to enhance precision and stable molding.

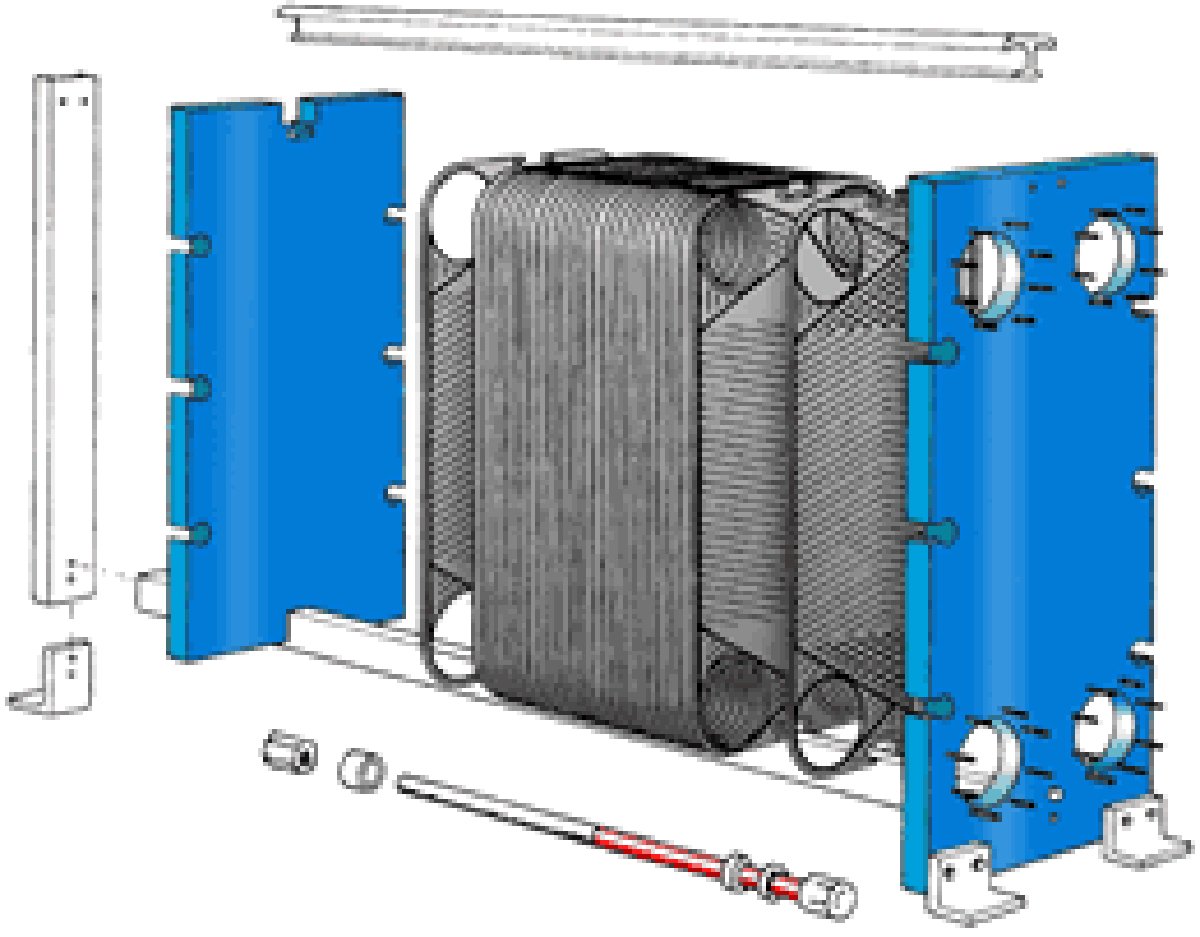

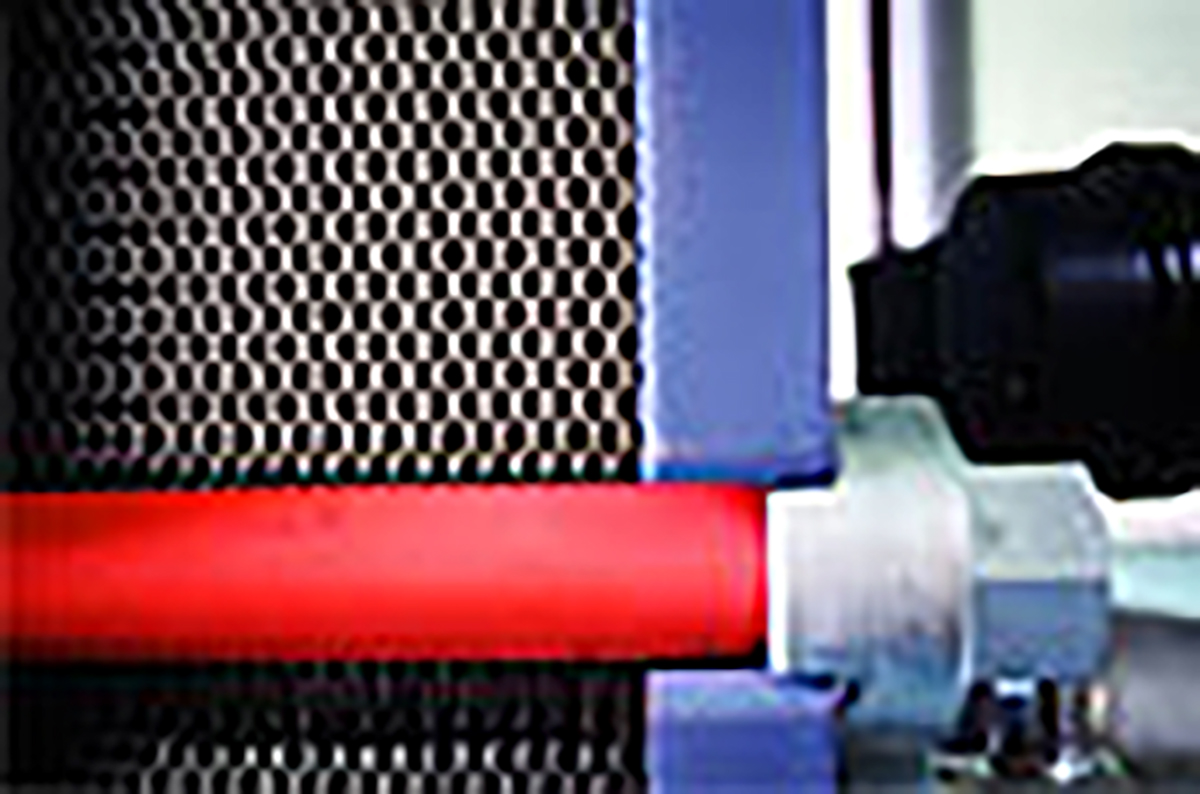

High efficiency plate heat exchanger

Plate heat exchanger with high heat transfer performance, the core of secondary cooling unit.

【Simple construction】

Simple flame work allows easy extension and maintenance.

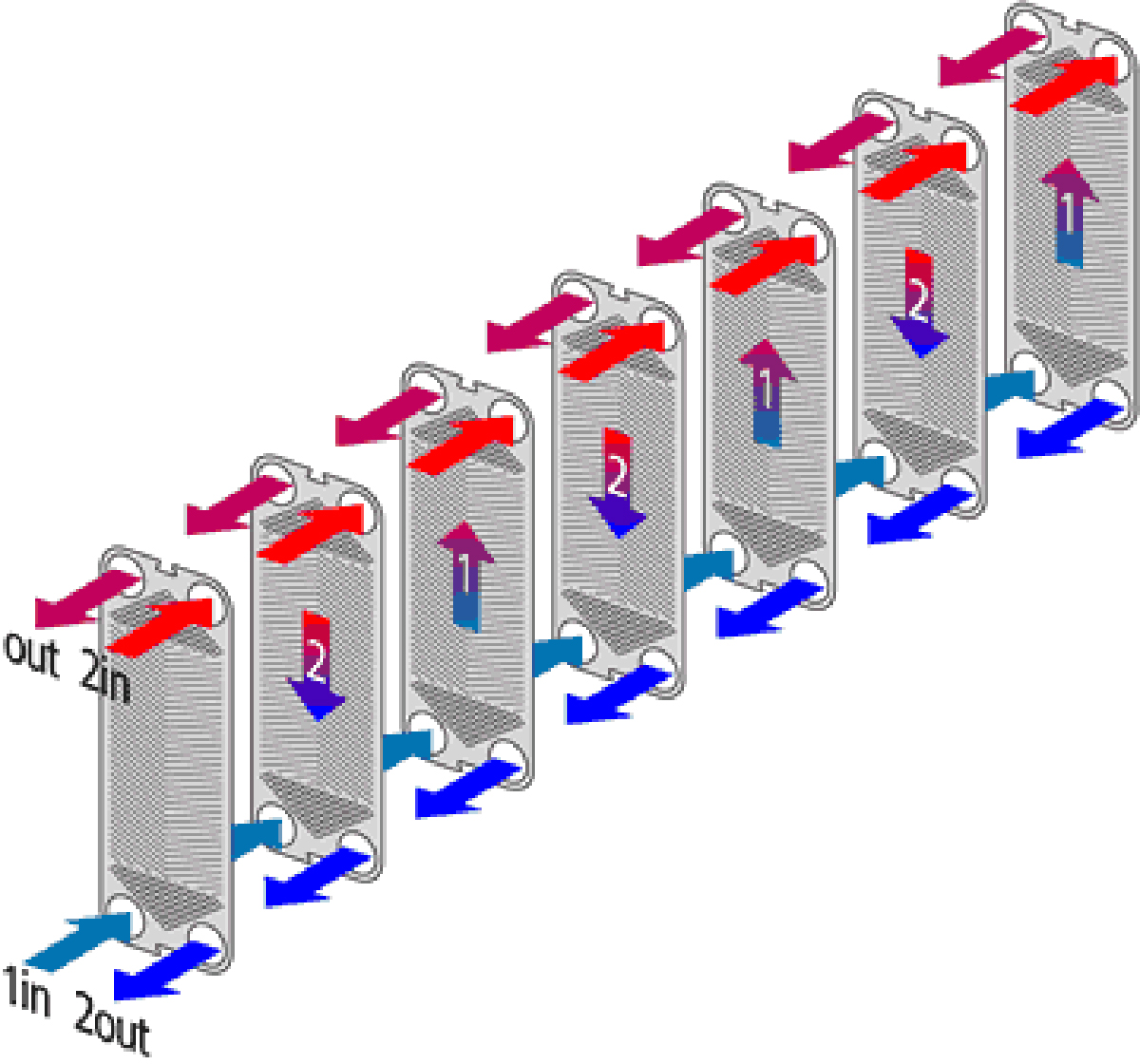

【Complete counter current flow enables highly efficient heat transfer】

Numbers show primary or secondary side.

Gaskets are fixed to each plate prevent two cooling water from mixing.

Heat exchanger plates used for 6 months

A great deal of deposit on primary side (left), no fouling on secondary side.

These photos show effect of the secondary cooling system on fouling prevention.

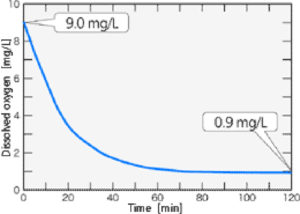

Removal of dissolved oxygen, the main cause of corrosion

Bring about clean and superb effect of anti-corrosion.

Actual deoxidization

Measured decrease in dissolved oxygen in the tank of cooling unit

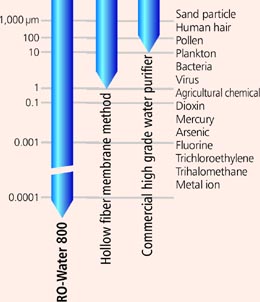

Removal of causative substance of scale and slime

Thorough removal of fine contaminations by reverse osmosis method

Comparison of removal performance

Examination of anti-rust effect

Untreated (left), O2-Free Air.

Metal piece, iron and copper, soaked in water for 7 days.

Stable anti-rust function irrespective of water temperature by a compact device.

Need no power supply and energy saving operation.

Available 800 little/day of pure water from tap water.

Long-life elements, automatic backwashing, easy maintenance and user friendliness.

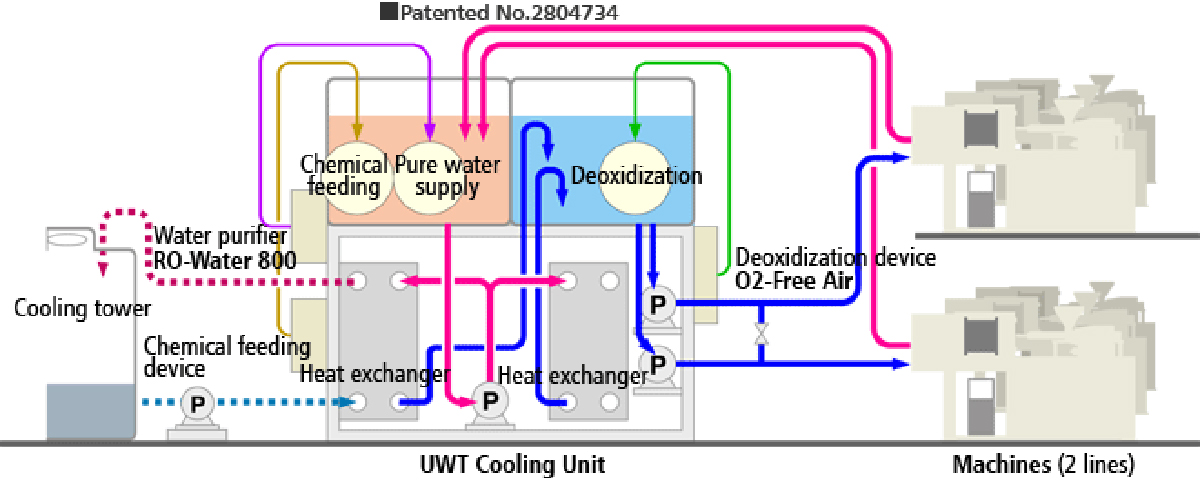

Dual system designed with productivity and easy maintenance

Two heat transfer units and two lines of piping for machines are installed.

No machine stoppage for maintenance, no production loss.

Variable control of water flow using inverter pump

Inverter pumps are used for piping for machines to control the water flow.

Adequate water supply helps energy saving operation.

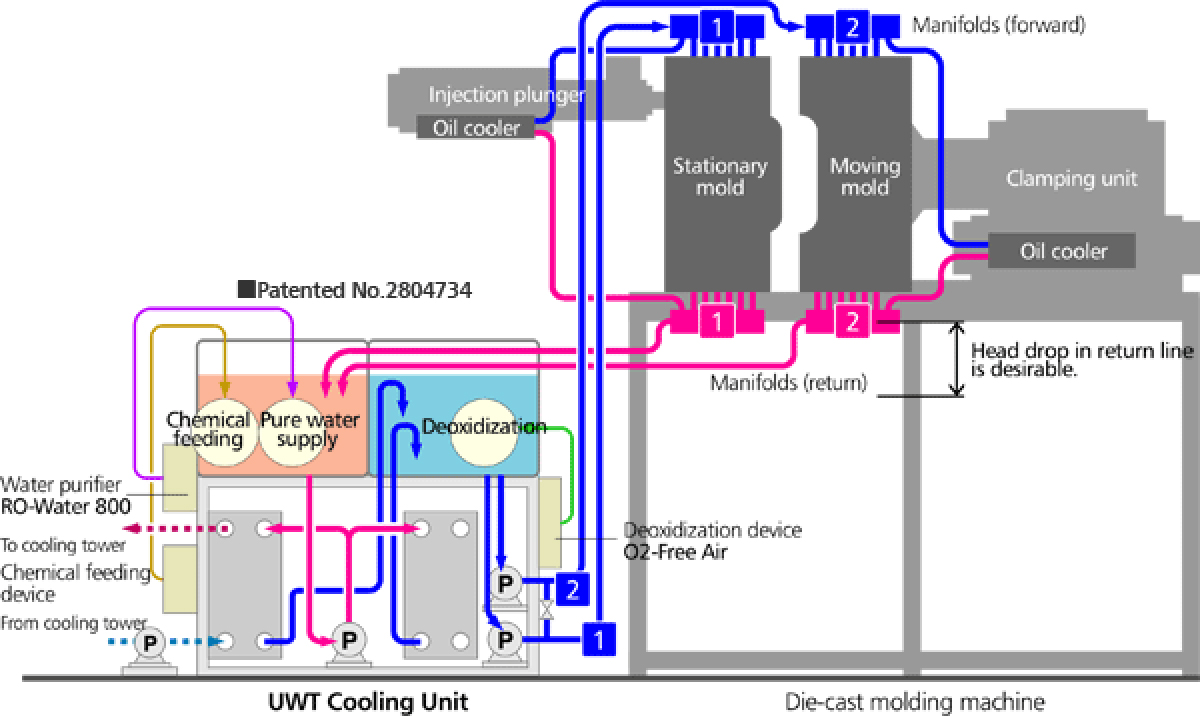

Secondary cooling system for die-cast molding

You can convert the existing cooling system into closed circuit only by installing UWT Cooling Unit

Controlled cooling water prevents clogging of piping or scraping of mold.

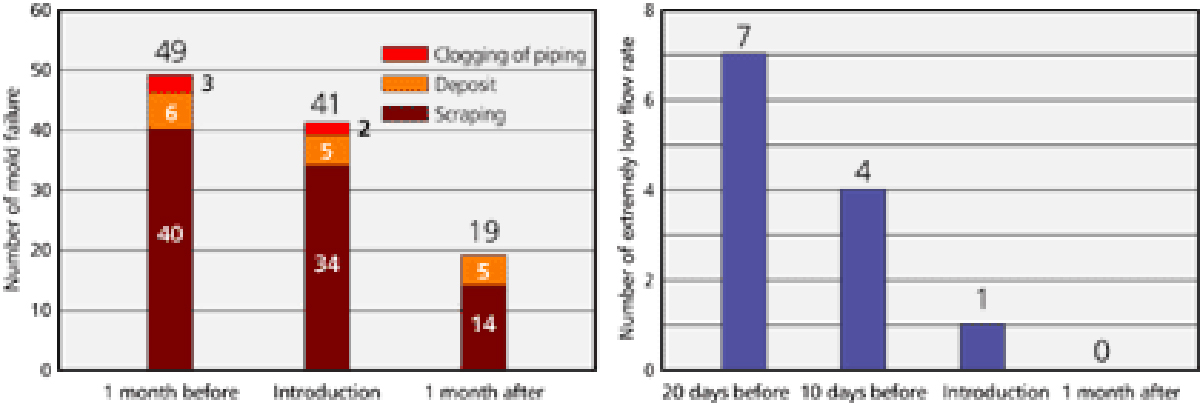

Prominent improvement is obtained only by introduction of UWT Cooling Unit into conventional open system using a pit.

【Change in the number of mold failure (left) and the number of extremely low flow rate】

Crankcase mold (2,000 tf class)

| Sampling date | Water quality criteria | Soon after introduction | 20 days after | ||

| Sample | Supply water | Cooling water | Tank of secondary cooling unit | Tank of secondary cooling unit | |

| Electrical conductivity(μS/cm) | <1200 | 270 | 821 | 343 | 273 |

| Turbidity | <20 | 0 | 1 | 9.3 | 0 |

| pH | 8.0-9.0 | 7.13 | 8.48 | 7.60 | 7.20 |

| Total hardnes(mg CaCO3/L) | 76 | 270 | 95 | 62 | |

| Chloride concentration(mg CT/L) | 23 | 60 | 26 | 6 | |

| Total iron concentration(mg Fe/L) | <1.0 | 0.20 | 0.60 | 2.37 | 0.15 |

| Oxygen concentration(mg/L) | 5.59 | 10.05 | 2.70 | 1.10 | |

● The water quality criteria is a reference value set by the factory.

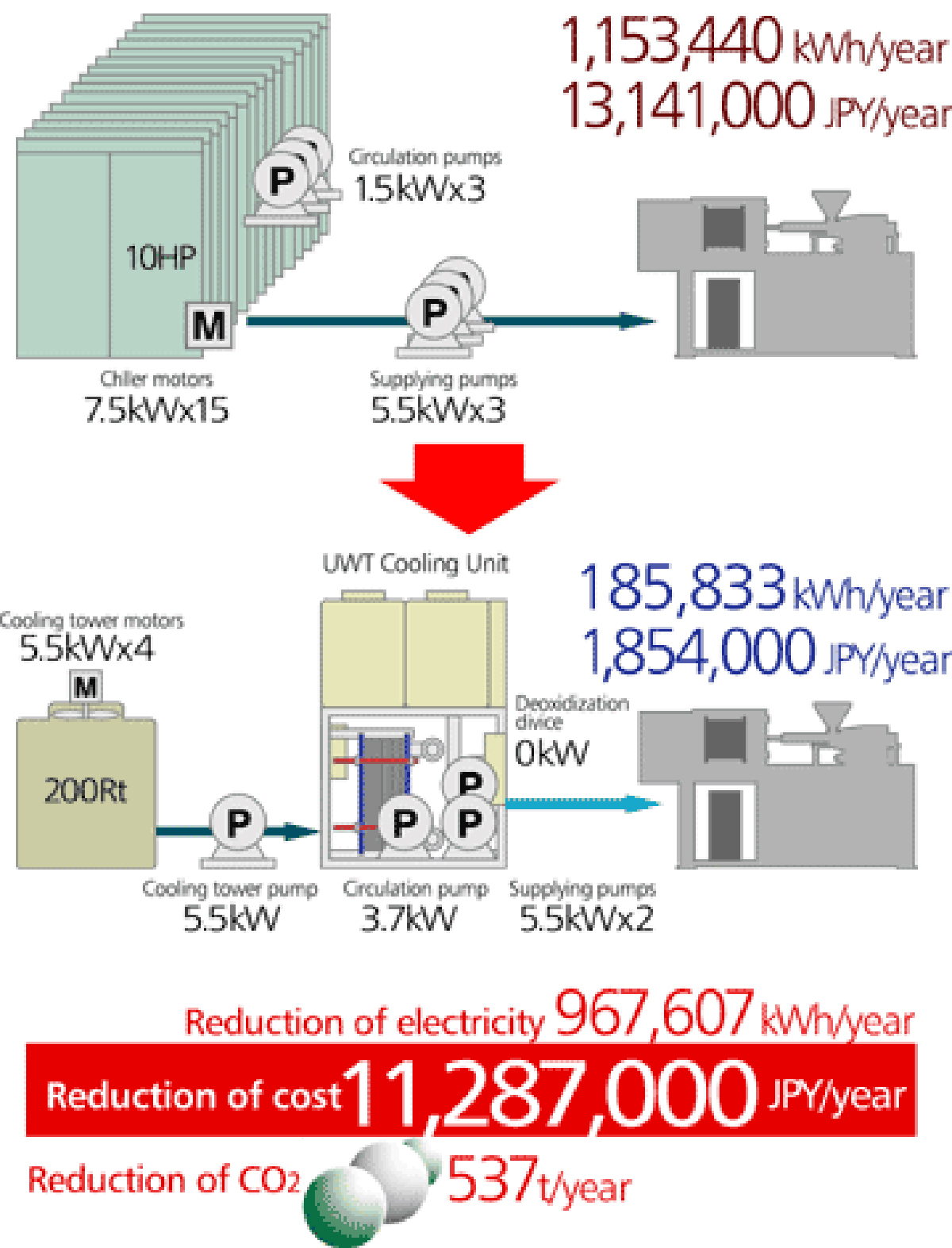

Reduce running cost by energy and work saving

■ Adequate pumping capability

Variable control by inverter pump is important. For Example, 20% of rev. down reduces electricity by half.

■ Mitigation of maintenance

Eliminate failure of equipments caused by cooling water.

■ Control of cooling water temperature

Excess cooling is prevented by automatic ON-OFF control.

■ Minimum use of chillers

Sufficient and stable supply is more effective than too low water temperature.

■ CO2 reduction

Power reduction is directly connected to CO2 cut.

Comparison of before and after introduction of UWT Cooling Unit

Easy construction, easy maintenance

UWT Cooling Unit is easily introduced into existing systems.Maintenance is easy, but check out water condition every day.

Cleaning of heat exchanger plates: 1 year

Replacement of filter: as needed

Replacement of membrane of RO water purifier: 3 years

Replacement of deoxidization separator: 1 year

Replenishment of chemical: as needed